Furniture Hardware Industry in India: From Local Craftsmanship to Global Engineering Excellence

Strong, precise, and design-driven — India’s furniture hardware industry has evolved from traditional metal workshops into a globally recognized sector. Once limited to local carpentry and handcrafted fittings, it now stands as a major exporter of precision-engineered hardware components to global markets such as the USA, UAE, Germany, and the UK.

Is Furniture Hardware Popular in India?

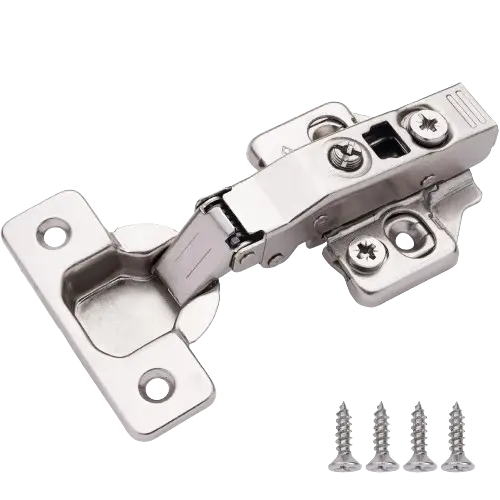

Yes — furniture hardware is one of the most essential and fast-growing segments in India’s construction and interior design ecosystem. With the rise of modular kitchens, luxury interiors, and commercial furniture systems, demand for hinges, locks, slides, handles, and connectors has skyrocketed.

Indian consumers today seek durable, stylish, and functional furniture accessories, driving local production and innovation.

What makes it more remarkable is that India doesn’t just use this hardware — it manufactures and exports it worldwide under global standards like ISO, CE, and BIS certifications.

Is It an Indian Industry?

Yes — while modern hardware technology was once influenced by European engineering, India has now mastered the art of indigenous design and precision manufacturing.

Leading Indian producers handle everything from casting and polishing to assembly and export within the country. This makes it a true “Made in India” success story — aligned with the Make in India initiative and global sustainability goals.

Key Growth Drivers:

Cost-efficient engineering and skilled craftsmanship

Advanced automation and CNC machining

Compliance with global quality and safety standards

Manufacturing Excellence in India

India’s furniture hardware sector merges modern automation with traditional metalworking expertise.

Core materials — stainless steel, brass, aluminum, and zinc alloys — are chosen for their durability, corrosion resistance, and aesthetic appeal.

Key Stages of Production

- Material Selection: Use of premium, corrosion-resistant metals

- Casting & Forging: CNC precision, die-casting, and high-tolerance machining

- Surface Finishing: Polishing, buffing, and electroplating for durability and shine

- Assembly & Testing: ISO/CE-certified endurance, torque, and corrosion tests

- Packaging & Logistics: Eco-safe, moisture-proof export packaging

Modern factories also use robotic finishing, powder coating, and water recycling systems, aligning with international environmental standards.

Major Manufacturing Hubs in India

| Region / City | Specialization | Industry Origin / Age |

|---|---|---|

| Jamnagar, Gujarat | Brass hinges, handles, knobs, and connectors | Established in 1940s–1950s — Known as “Brass City of India”, home to thousands of brass hardware manufacturers and exporters |

| Aligarh, Uttar Pradesh | Locks, latches, and architectural hardware | Origin dates back to early 1900s — One of India’s oldest lock and hardware manufacturing hubs |

| Rajkot, Gujarat | Stainless steel fittings, cabinet hardware, and modular components | Industrial growth since the 1970s–1980s, now a leading center for precision and stainless steel hardware |

| Mumbai & Pune, Maharashtra | Decorative fittings, premium architectural hardware, and designer handles | Industry developed in 1960s–1970s, with expansion during the modern interior boom of the 2000s |

| Delhi NCR (Noida, Ghaziabad, Gurugram) | Modular kitchen accessories, wardrobe systems, and office hardware | Emerged in the 1990s–2000s with the rise of modular furniture and real estate development |

| Chennai & Coimbatore, Tamil Nadu | Casters, furniture legs, and industrial fittings | Developed around 1980s–1990s, now strong in industrial and export-oriented hardware manufacturing |

These hubs support both OEMs (Original Equipment Manufacturers) and export houses, supplying sectors such as furniture, real estate, hospitality, and interior design.

Export and Global Reach

India’s furniture hardware exports continue to expand due to competitive pricing, design innovation, and consistent quality.

Indian hardware now enhances furniture in homes, hotels, and offices across the world.

Top Export Destinations

UAE, USA, UK, Germany, Saudi Arabia, Australia, South Africa, Canada, and Southeast Asia.

Export Authorities and Certifications

EEPC India: Promotes engineering goods and metal hardware exports

BIS: Ensures national quality compliance

FIEO: Facilitates export development and trade support

FIEO: Facilitates export development and trade support

Export Highlights

Growing demand for modular and decorative fittings

OEM collaborations with international brands

Rising preference for stainless steel and eco-safe materials

Expanding exports via trade fairs and e-commerce platforms

Leading Indian Manufacturers and Exporters

| Company / Brand | Headquarters | Key Export Products | Established / Incorporation Year |

|---|---|---|---|

| Hettich India Pvt. Ltd. | Gurgaon, Haryana | Drawer systems, hinges, fittings | 1999 |

| Ebco Pvt. Ltd. | Mumbai, Maharashtra | Modular furniture hardware, office fittings | 1963 |

| Godrej Locks & Architectural Fittings | Mumbai, Maharashtra | Locks, handles, and smart hardware | 1897 |

| Kich Architectural Products Pvt. Ltd. | Rajkot, Gujarat | Stainless steel hardware, railing systems | 1992 (Export unit), incorporated 2003 |

| Ozone Overseas Pvt. Ltd. | Delhi NCR | Glass fittings, door and bathroom hardware | 1999 |

| Link Locks Pvt. Ltd. | Aligarh, Uttar Pradesh | Door locks, latches, and security fittings | 1986 |

Mumbai, Maharashtra Delhi / Noida, Uttar Pradesh | Premium kitchen and furniture fittings Hinges, handles, locks, latches, industrial hardware | 2007 1948 |

India’s Competitive Advantage

India’s Competitive Advantage

Lower production costs compared to Europe and China

Skilled labor and design innovation

Strong logistics network via ports in Gujarat, Maharashtra, and Tamil Nadu

Stringent quality testing and certification compliance

Government incentives through Make in India, MSME, and EPCG schemes

Future Outlook

The future of India’s furniture hardware industry is bright and expanding, with double-digit export growth expected in the next decade.

By 2030, India aims to be among the top five furniture hardware exporters, crossing USD 3 billion in annual exports.

Emerging Industry Trends:

Smart and modular furniture hardware

AI-based automated production lines

Strategic collaborations with global brands

Recyclable and sustainable material innovation

Conclusion

From local brass workshops in Jamnagar to luxury furniture showrooms in London and Dubai, India’s furniture hardware industry represents precision, reliability, and craftsmanship.

With robust engineering, design innovation, and global quality standards, Indian manufacturers are reshaping the world’s furniture ecosystem — proving that true strength lies in the hardware that holds everything together.

Post Comment