Dies & Moulds: An Iconic Indian Ethnic Product

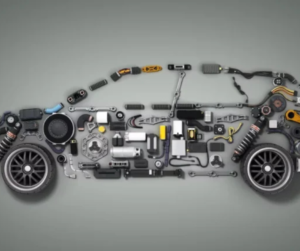

India’s rich tradition of craftsmanship goes far beyond textiles, jewelry, and handicrafts. One of its lesser-known but highly significant contributions to global manufacturing is the production of dies and moulds. These precision tools are indispensable for shaping metals, plastics, and other materials across multiple industries, including automotive, electronics, packaging, and healthcare. While often overlooked, dies and moulds are a cornerstone of India’s industrial identity and a testament to the country’s blend of artistry and technical expertise.

History and Cultural Significance

The craft of die and mould making in India has roots stretching back thousands of years. Archaeological evidence from the Indus Valley Civilization reveals advanced metallurgical techniques, including the lost-wax (cire perdue) casting method, used to create intricate bronze artifacts like the famous Dancing Girl from Mohenjo-Daro.

In the lost-wax method, artisans create a wax model of the desired object, coat it with clay, and then heat it to remove the wax. The resulting cavity is filled with molten metal to form a precise replica of the original model. This technique not only ensured artistic finesse but also introduced India’s early mastery of precision in manufacturing.

Even today, traditional mould-making practices survive in places like Swamimalai, Tamil Nadu, where artisans continue to produce intricate bronze sculptures and religious icons using centuries-old methods. These practices highlight how mould making has historically combined functionality with artistic and spiritual significance, making it an integral part of India’s cultural and industrial heritage.

Origin City/Region

While die and mould making is practiced across India, certain regions have become synonymous with precision craftsmanship and industrial excellence:

Ghaziabad, Uttar Pradesh: Situated near Delhi, Ghaziabad has emerged as a leading hub for industrial tooling. The city houses numerous manufacturers specializing in dies and moulds for automotive, packaging, and consumer goods sectors. Companies here export to global markets including the United States, Spain, and the United Kingdom.

West Bengal: In Bengal, traditional mould-making techniques remain highly artisanal. Craftsmen use clay-based moulds, applying natural binders and fuel sources such as cow dung cakes to create durable and highly detailed patterns. These methods, while labor-intensive, preserve India’s centuries-old artisanal legacy and ensure exceptional quality in finished products.

These regions exemplify the balance between heritage craftsmanship and modern industrial manufacturing, reinforcing India’s reputation as a global supplier of high-quality dies and moulds.

Traditional Making Process

The process of crafting dies and moulds in India is highly methodical, combining skill, precision, and time-tested techniques:

Design and Pattern Creation

Artisans begin by designing the component, either via hand sketches or CAD software for precision.

A replica of the component, called a pattern, is created from wax, clay, or wood.

Mould Formation

The pattern is coated with fine sand mixed with a binding agent, forming a protective shell around it.

The shell is heated to remove the pattern, leaving a cavity that mirrors the shape of the component.

Metal Casting or Injection

Molten metal, commonly aluminum, zinc, or steel, is poured or injected into the cavity.

The material cools and solidifies, taking the exact shape of the mould.

Finishing and Quality Checks

After cooling, the mould is carefully removed.

Excess material is trimmed, polished, or coated to achieve the desired finish and ensure compliance with international standards.

This meticulous process ensures high precision and durability, which is why Indian dies and moulds are recognized and appreciated in global markets.

Global Appeal and Recognition

India’s dies and moulds industry has gained international recognition for its quality, cost-effectiveness, and reliability. A combination of skilled artisans, technological integration, and adherence to global standards has positioned India as a preferred outsourcing destination for tooling solutions.

Export Markets: Indian dies and moulds are exported worldwide, with major buyers in the United States, Europe, the Middle East, and Africa. Countries like Saudi Arabia, Bahrain, and Uganda consistently import high-quality Indian tooling solutions.

Technological Edge: Many Indian manufacturers now integrate simulation technologies, CNC machining, and additive manufacturing to enhance precision and reduce lead times. This blend of traditional craftsmanship and modern technology gives Indian dies and moulds a competitive edge in the international market.

Cost Advantage: India’s competitive labor costs combined with expertise ensure that international buyers receive high-quality products at optimal pricing, contributing to strong global demand.

Brand Spotlight: PMD

To illustrate India’s global presence in the die and mould sector, consider PMD, one of the country’s leading manufacturers:

Overview: PMD specializes in precision moulds and dies for multiple industries, including automotive, consumer goods, and packaging.

Founder: Established by Mr. Ravindran Pillai, PMD began with a vision to bring world-class tooling expertise to India.

Year Established: 1973

Exports: PMD exports its products to several international markets, demonstrating the global trust in Indian-made tooling solutions.

Reputation: While exact turnover data is not publicly disclosed, PMD’s longevity and recognition speak to its scale, quality, and reliability.

PMD’s success reflects the international acknowledgment of Indian dies and moulds as high-precision, dependable, and competitively priced products.

Conclusion

India’s die and mould industry stands as a symbol of national pride, combining centuries-old artisanal traditions with modern engineering precision. From ancient lost-wax casting to high-tech CNC moulding, Indian manufacturers have continually evolved to meet international standards without losing touch with their cultural roots.

The global recognition, steady export demand, and adaptability of Indian dies and moulds highlight their importance not only to India’s economy but also to the worldwide manufacturing ecosystem. They are a testament to India’s ingenuity, skill, and commitment to excellence—truly a product that is “Proudly Made in India.”